Used properly, Personnel Protective Equipment (PPE) greatly reduces the risk of injury and minimizes the effects of toxins. PPE is required in the Laney College welding lab. If you do not wear approved PPE, you will not be allowed in the lab. Used properly, Personnel Protective Equipment (PPE) greatly reduces the risk of injury and minimizes the effects of toxins. PPE is required in the Laney College welding lab. If you do not wear approved PPE, you will not be allowed in the lab.

You are required to provide your own PPE for the lab. The following table lists PPE that is required (indicated with an “R”) and optional (indicated with an “O”). A description of each item is listed below, along with recommendations. |

OAW GogglesOOOOO

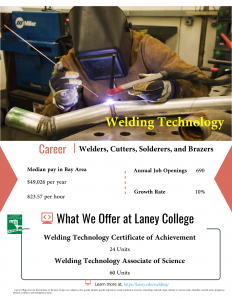

| Course Number | Weld 205 | Weld 203A-D | Weld 204A-D | Weld 211A-D | Weld 221A-D |

| Course Title | Introduction to Welding |

GTAW (TIG or Heli-Arc) |

SMAW (Arc or Stick) |

GMAW (Wirefeed or MIG) |

OAW (Oxy-Acetylene) |

| Welding cap | R | R | R | R | R |

| Safety glasses | R | R | R | R | R |

| Earplugs | R | R | R | R | R |

| Gloves | R | R | R | R | R |

| Respirator or Dust mask | R | R | R | R | R |

| Jacket (long sleeved, high collar shirt) | R | R | R | R | R |

| Long pants, no sagging | R | R | R | R | R |

| Close-toed leather shoes | R | R | R | R | R |

| Welding helmet | O | O | O | O | O |

| Face shield | O | O | O | O | O |

Welding Cap height=”300″ A welder’s cap should be worn to protect the head from hot metal and slag splatter. In addition, long hair should be tied back and tucked inside the welding jacket. Baseball caps that are made of cotton are allowed. Hats that are mainly polyester or have significant plastic content are not allowed.Recommended: Cotton welding caps or cotton doo-rags. |

Eye protection height=”166″ Safety glasses for use over glasses  height=”166″ Safety glasses Approved eye protection must be worn at all times while in the lab. This can be safety glasses or goggles. Eye protection must fit properly, and be in good condition. It must be properly worn, protecting the user’s eyes at all times. Mirrored or heavily colored lenses do not protect the eyes and are not approved for use in the welding laboratory. Eye protection must meet American National Standards Institute standards: ANSI Z87.1-1989, blocking 99% UVA and 60% UVB.Recommended: Clear ANSI 87.1 compliant safety glasses made of polycarbonate. Prescription glasses must be covered by safety glasses, prescription safety glasses with side shields are recommended. |

Hearing Protection Silicon ear plugs with string attachment and case There are many noise-generating devices in the welding laboratory that can damage your hearing, and there are circumstances in which debris can penetrate the ear canal. Earplugs are required to protect your ears from both loud noises and foreign object damage. Ear muffles can be worn to provide even greater noise reduction.Recommended: Washable Silicon earplugs on a string. |

Gloves

Leather welding gloves are required to protect the hands while welding. They should match the welding process that you are performing. Thick leather welding gloves are recommended for SMAW and FCAW. High-temperature welding gloves are recommended for FCAW. Medium-weight welding gloves are recommended for GMAW. Thinner welding gloves that allow increased dexterity are recommended for GTAW and OAW. Gloves should not be used where the glove can get caught in rotating machinery, especially pedestal grinders. Recommended: Weld 205 Introductory Course: Medium weight GMAW (MIG) gloves, such as Black Stallion Mighty MIG or Miller MIG glove. Recommended: Weld 203A-D GTAW (TIG) classes: GTAW (TIG) gloves. Recommended: Weld 204A-D SMAW (Arc weld or STICK) classes: Medium weight GMAW (MIG) gloves, such as Black Stallion Mighty MIG or Miller MIG glove. Recommended: Weld 211A-D Wire Feed classes: Medium weight GMAW (MIG) gloves, such as Black Stallion Mighty MIG or Miller MIG glove. Recommended: Weld 221A-D OAW (Oxygen-Acetylene or gas welding) classes: Medium weight GMAW (MIG) gloves, such as Black Stallion Mighty MIG or Miller MIG glove.  Heavy weight glove for SMAW or FCAW  Medium weight welding glove for OAW, GMAW or SMAW  Tig gloves |

Breathing Protection

There are many fumes and gases produced from welding and associated processes. It is highly recommended that a filter mask or a ½-mask respirator be worn for welding and grinding. FCAW, SMAW and grinding are processes that produce fumes and particulates.Nuisance filter masks, type N95 with charcoal, are recommended as minimum protection. The N95 filters 95% of particles 0.3 micrometers (µm) and larger, while the charcoal filter reduces ozone (O3) created in the weld process. For heavy particulate generation and harmful materials (for example, chromium 6+), a ½-mask respirator with P100 filter with charcoal filter is highly recommended. A P100 filters 100% of particles 0.3 micrometers (µm) and larger. P100’s are also called high efficiency particulate absorbing (HEPA) filters. As with the N95’s, the charcoal filter reduces ozone (O3). Highly recommended: half-mask Respirator with a P100 filter and charcoal filter (for example, 3M part number 2097). Recommended: N95 or N100 mask. NOTE: if you have respiratory health issues you should consult with your doctor first before use and read the manufacture instructions regarding use.  Half mask respirator  N95 or N100 mask

P100 particulate filter with charcoal |

Clothing

Proper clothing can provide a great amount of protection. Welding students are required to wear natural fiber materials, such as cotton or wool. Long sleeved shirts and long pants are also required. A welding jacket is highly recommended. Items that are not allowed include fleece jackets or pants (polyester fibers) or pantyhose (nylon). Pants should not have cuffs that can catch sparks or hot slag. Sagging is not allowed for the same reason. Frayed clothes or clothes that have holes are not allowed. Recommended: Natural fiber such as cotton or leather. For FCAW and SMAW processes, leather or welding-approved jacket is highly recommended. Leather chaps that cover the legs are also encouraged. |

Shoes

Proper shoes will protect your feet from hot sparks or falling objects. Here are some guidelines for buying protective footwear. The protective footwear you choose should comply with the American Society for Testing and Materials (ASTM) standard F2413-05, which separates safety footwear into different categories such as Impact and Compression Resistance.Impact and compression resistant footwear is constructed with a toe-cap to protect your foot from falling objects that could crush or break your toes. The new ASTM F2413-05 standard does not approve of “strap-on” toe-caps. Any protective toe-cap must be designed and constructed into the shoe during the manufacturing process and tested as an integral part of the footwear in order to protect feet. Also, safety toe shoes/boots are tested to meet one of two units of measurement for impact rating i.e.75 or 50 foot-pounds. A foot-pound is determined through a test, which is performed by dropping a steel weight from a predetermined height at a designated speed. For example, I/75 rated shoes/boots will protect a worker from an impact of 75 foot-pounds. You can determine if your footwear complies with the ASTM F2413-05 standard by looking for this type of information on the label. ASTMF2413-05 or M/I/75/C/75 ASTM F2413-05: The letters F2413 reference the performance requirement for foot protection. The additional digits following the standard designation indicate the year of the standard to which the protective footwear complies, for example: 05 refers to 2005. M = Footwear designed for a male. Recommended: Closed-toed shoes are required. Leather shoes are recommended. Leather high top work boots or metal-toe safety shoes are highly recommended. |

Welding Helmet

A limited number of welding helmets are provided for use in the laboratory. SMAW, FCAW, GMAW, GTAW and plasma cutting require a welding helmet with a welding approved shaded lens. The amperage used during the welding process determines the lens shade. See Table 1 for recommendations as specified by the ANSI Z49.1 Recommended: students are encouraged to wait to buy a helmet. Because there is such a large range of helmet types and prices the choice is highly dependent on the welding process(es), frequency, environment and fit.

|

Guide for shade numbers

| Operation | Electrode size in 1/32in. (mm) |

Arc current |

Minimum protective shade |

Suggested shade (comfort) |

| SMAW | Less than 3 (2.5) | Less than 60 | 7 | – |

| 3-5 (2.5-4) | 60-160 | 8 | 10 | |

| 5-8 (4-6.4) | 160-250 | 10 | 12 | |

| More than 8 (6.4) | 250-550 | 11 | 14 | |

| GMAW / FCAW | Less than 60 | 7 | – | |

| 60-160 | 10 | 11 | ||

| 160-250 | 10 | 12 | ||

| 250-550 | 10 | 14 | ||

| GTAW | Less than 50 | 8 | 10 | |

| 50-150 | 8 | 12 | ||

| 150-500 | 10 | 14 | ||

| Air Carbon / Arc Cutting | Light | Less than 500 | 10 | 12 |

| Heavy | 500-1000 | 11 | 14 | |

| Plasma arc welding | Less than 20 | 6 | 6 to 8 | |

| 20-100 | 8 | 10 | ||

| 100-400 | 10 | 12 | ||

| 400-800 | 11 | 14 | ||

| Plasma arc cutting | Light | Less than 300 | 8 | 9 |

| Medium | 300-400 | 9 | 12 | |

| Heavy | 40-800 | 10 | 14 | |

| Torch brazing | 3 or 4 | |||

| Torch soldering | 2 | |||

| Carbon arc welding | 14 |

Face shields

Additional eye protection is required over safety glasses for certain tasks. For processes that will produce high velocity particles, a full-face shield is required. A face shield is required for using portable grinders, pedestal grinders, abrasive cut-off saws, and sanders. |

Goggles

Oxy-Fuel welding and cutting requires welding goggles. Goggles protect the eyes from the intense light and IR (infrared) from the flame. Goggles should have minimum shade number of 5. |