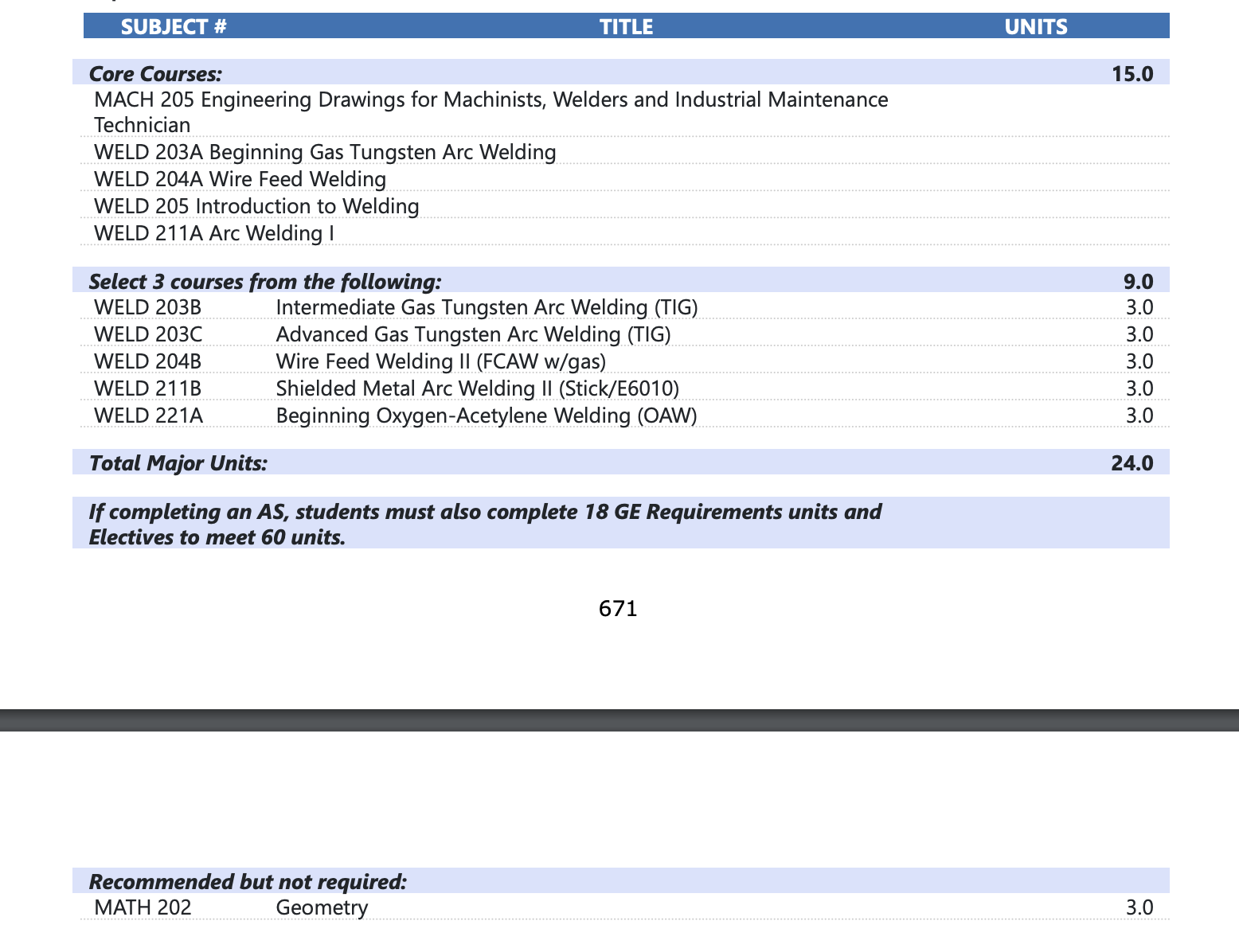

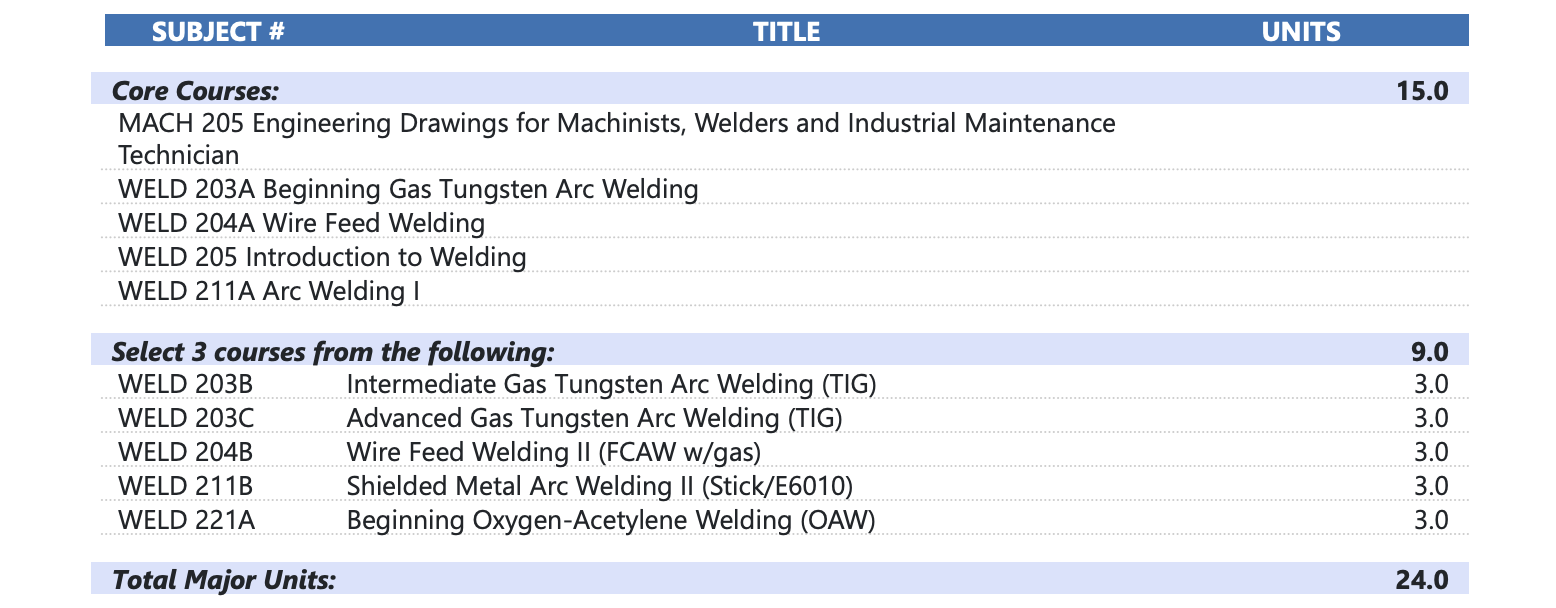

Associate Degree

Welding Technology – A.S. Degree

Welding Technology offers an opportunity to learn cognitive and manipulative welding skills which prepare the student for employment in occupations that use welding applications.

Program Learning Outcomes

Upon completion of this program a student will be able to:

1. Students will recognize the value of wearing safety glasses in the lab by: 1) describing the dangers to the eyes in the welding lab, (such as UV rays, projectiles, chemicals and sparks/molten material); 2) complying consistently with the Department policy of always wearing safety glasses in the lab.

2. Students will determine several advantages and disadvantages of a given welding process, and differentiate between different welding processes.

3. Students will correctly list steps for setup and shut down of regulator and torch set for Oxy Acetylene welding. In the lab, they will perform these steps and correctly adjust for a neutral flame.

4. Students will set up an arc welding power supply and its related components for SMAW, GMAW and GTAW processes, strike an arc, and complete a weld in the flat position compliant with AWS D1.1 code standards.

Career Opportunities

Welding is a lead skill in many construction and manufacturing industries, including industrial maintenance, petroleum, cross-country gas transmission, fabrication of goods and equipment, aerospace, food manufacturing, and biotech. Job titles include both manual welders and welding support personnel, including ironworkers, pile drivers, millwrights, fabricators, welding supplies and equipment sales, weld inspection and weld engineers.

Certificate of Achievement

Welding Technology – Certificate of Achievement

Welding Technology offers an opportunity to learn cognitive and manipulative welding skills which prepare the student for employment in occupations that use welding applications.

Program Learning Outcomes

Upon completion of this program a student will be able to:

1. Students will recognize the value of wearing safety glasses in the lab by: 1) describing the dangers to the eyes in the welding lab, (such as UV rays, projectiles, chemicals and sparks/molten material); 2) complying consistently with the Department policy of always wearing safety glasses in the lab.

2. Students will determine several advantages and disadvantages of a given welding process, and differentiate between different welding processes.

3. Students will correctly list steps for setup and shut down of regulator and torch set for Oxy Acetylene welding. In the lab, they will perform these steps and correctly adjust for a neutral flame.

4. Students will set up an arc welding power supply and its related components for SMAW, GMAW and GTAW processes, strike an arc, and complete a weld in the flat position compliant with AWS D1.1 code standards.

Career Opportunities

Welding is a lead skill in many construction and manufacturing industries, including industrial maintenance, petroleum, cross-country gas transmission, fabrication of goods and equipment, aerospace, food manufacturing, and biotech. Job titles include both manual welders and welding support personnel, including ironworkers, pile drivers, millwrights, fabricators, welding supplies and equipment sales, weld inspection and weld engineers.

Students can also specialize in a specific welding process, with the potential to certify to AWS code D1.1