Ready to Search for Available Classes?

Follow this link to the updated online class schedule!

To search for classes offered by the machine technology department, follow these steps:

- Select Term -> 2024 Spring

- Select Subject Area -> Machine Shop

- Select Campus -> Laney College

- Click -> Search

Please pay attention to the notes for each class section as they may contain important details about the mode of instruction.

CAD Solid Modeling with SolidWorks

Course Number: MACH 20

Units: 4

Class: 3 hours lecture, 3 hours laboratory

Acceptable for credit: CSU

Description: Fundamentals of Computer-Aided Design (CAD) using SolidWorks software: Application of SolidWorks in creating manufacturing models and documents including solid part models, assembly models and engineering drawings.

Introduction to CNC Programming and CAD/CAM Technology

Course Number: MACH 30

Units: 4

Class: 3 hours lecture, 3 hours laboratory

Prerequisite: Mach 210

Acceptable for credit: CSU

Description: Introduction to programming of Computer Numerical Control (CNC) machines using standard programming methods: Safety procedures, tool and work setups, and mill and lathe operation.

Advanced CNC and CAD/CAM Programming

Course Number: MACH 31

Units: 4

Class: 3 hours lecture, 3 hours laboratory

Acceptable for credit: CSU

Prerequisite: MACH 30

Description: Advanced programming of Computer Numerical Control (CNC) machines using CAD/CAM software: Mastercam for mill 2D, including high speed toolpaths, and lathe operations.

New for 23-24! Multi-Axis CNC Machining

Course Number: MACH 32

Units: 4

Class: 3 hours lecture, 3 hours laboratory

Acceptable for credit: CSU

Prerequisite: MACH 31

Description: Multi-axis programming of Computer Numerical Control (CNC) machines using CAD/CAM software: Mastercam for mill 3D, 4 and 5 axis indexed and simultaneous milling, and lathe operations with live tooling and C-/Y-axis control.

Geometric Dimensioning and Tolerancing

Course Number: MACH 75

Units: 2

Class: 2 hours lecture

Prerequisite: MACH 205 or MACH 210

Acceptable for credit: CSU

Description: Interpretation of print specifications and inspection criteria related to ASME Y14.5 -2018 Geometric Dimensioning and Tolerancing standard: Language and methodology used by industry to define the shapes of, and relationships between, part features in design, manufacture and quality control.

Special Projects Laboratory

Course Number: MACH 200

Units: 1-4

Class: 3-12 hours laboratory

Prerequisite: MACH 210

Description: Open laboratory for working on selected projects: Provides the opportunity for development of individual interests.

Engineering Drawings for Machinists, Welders, and Industrial Maintenance Technicians

Course Number: MACH 205

Units: 3

Class: 3 hours lecture

Description: Interpretation of engineering drawings and specifications for machinists, welders, and industrial maintenance technicians: Explanation of rules, symbols and specifications in drawings (“blueprints”) for parts, assemblies and weldments; Introduction to ASME Y 14.5 Geometric Dimensioning and Tolerancing (GD&T) standard.

Industrial Hydraulics & Pneumatics

Course Number: MACH 206

Units: 2

Class: 1 hours lecture, 3 hours laboratory

Description: Introduction to theory and operation of hydraulic and pneumatic systems: Hydraulic and pneumatic principles, components, symbols, and applications from systems development and troubleshooting perspectives; Operation and interaction of hydraulic and pneumatic components in circuits; Maintenance and troubleshooting procedures for systems, system components and manufacturing assembles.

Theory, Operation, and Maintenance of Mechanical Drives

Course Number: MACH 207

Units: 3

Class: 2 hours lecture, 3 hours laboratory

Prerequisite: MACH 210

Description: Introduction to theory, operation and maintenance of mechanical drive components and power transmission systems: Troubleshooting, preventive maintenance, repair of rotary and linear motion components, including bearings, couplings, belt drives, chain drives, gear drives, conveyors, clutches, brakes, adjustable speed drives and linear motion devices, as well as topics such as lubrication and alignment.

Machine Technology I

Course Number: MACH 210

Units: 5

Class: 3 hours lecture, 6 hours laboratory

Description: Introduction to the theory and operation of machine tools: Shop safety, blueprint reading and engineering drawings, precision measurement, layout, tool grinding, speed and feed calculations, drill press operation, lathe setup and operation and mill setup and operation.

New for 23-24! Ultraprecision and Micromachining

Course Number: MACH 214

Units: 4

Class: 2 hours lecture, 6 hours laboratory

Prerequisite: MACH 31

Description: Advanced topics in machining and metrology for demanding applications requiring the highest precision and the smallest features: Handling small delicate parts, kinematic design principles, vacuum and adhesive workholding, micromilling, diamond turning, and non-contact optical measurement methods, such as microscopy and interferometry.

Machine Technology II

Course Number: MACH 220

Units: 5

Class: 3 hours lecture, 6 hours laboratory

Prerequisite: MACH 210

Description: Continuation of MACH 210: Internal lathe operations; lathe workholding devices; four jaw chucks, mill head tramming and other indicator work; vertical mill setup, operation, and use of milling accessories; carbide tooling selection and geometries; introduction to Geometric Dimensioning and Tolerancing, including inspection methods.

Machine Technology III

Course Number: MACH 230

Units: 5

Class: 3 hours lecture, 6 hours laboratory

Prerequisite: MACH 220

Description: Continuation of MACH 220: Advanced topics such as industrial maintenance machining, machine tool maintenance, machine building, precision toolmaking, tool and cutter grinding, die- and moldmaking, gear cutting and theory; student selects multiple projects from those offered based on their area of interest; projects involve multiple machining operations, processing with multiple machine tools and multi-part assemblies; more in-depth coverage of properties of materials, including heat treatment, and Geometric Dimensioning and Tolerancing (GD&T), including inspection methods.

Survey Course for the Skilled Trades

Course Number: MACH 255

Units: .5

Class: 1.5 hours laboratory

Corequisite(s): CARP 255, WDTEC 255, WELD 255

Description: Introduction to the skilled trades Machining Topics include safety, career opportunities, and hands on experience. Part of a four part series survey class including WELD 255, CARP 255, WDTEC 255.

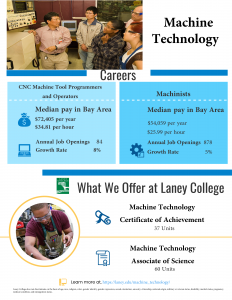

Occupational Work Experience in Machine Technology

Course Number: COPED 466L

Units: 1-4

Class: hours to be arranged

Description: Supervised employment providing opportunities in ma-chine technology or a related field: Develop desirable work habits, become a productive, responsible individual, and extend education experience with on the job training. Students may re-enroll for a maximum of 16 units for occupational or a combination of general and occupational work experience education (including Regular and Alternate Plan and General/Occupational/Apprentice Work Experience).