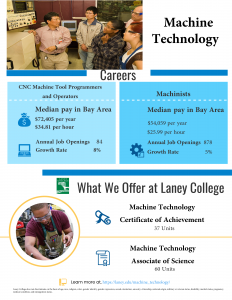

This is where you’ll find documentation for some of the projects in the Machine Technology department – both curriculum projects and other fun extracurricular projects.

Curriculum Projects

Finder Scope (more content coming throughout Fall 23 semester)

The Finder Scope is the new student project in MACH 210 – the introductory course in machining and manufacturing. You will become familiar with the operation of conventional machine tools like lathes and mills, but you will also be exposed to digital fabrication methods, like CNC machining, laser and water-jet cutting, and 3D printing, as well as to metal finishing techniques like anodizing. The Finder Scope itself is a low magnification refractor telescope with an integrated altitude-azimuth mount. It is intended to aid in finding objects of interest in the night sky when using the larger, higher magnification reflector telescope which will be the capstone project in the machine technology course sequence.

These videos are intended to be used in conjunction with a drawing packet and step-by-step manufacturing procedures:

Check out the Finder Scope Drawing Packet here!

Check out the Tube – Manufacturing Procedure here!

Check out the Shield – Manufacturing Procedure here!

Check out the Focuser – Manufacturing Procedure here!

Check out the Eyepiece Retainer – Manufacturing Procedure here!

Check out the Mount Lower – Manufacturing Procedure here!

Check out the Mount Intermediate – Manufacturing Procedure here!

Check out the Mount Upper – Manufacturing Procedure here!

Threaded Shaft

The Threaded Shaft is your introduction to the lathe. The lathe – with which a stationary cutting tool is brought into contact with a rotating workpiece to produce typically cylindrical shapes – is one of the most common machine tools. You will build upon what you have already learned about print reading, precision measurement, metal cutting operations and tool geometries. You will be introduced to lathe operation, tooling and safety. You will learn how to inspect precision screw threads.

Check out the Threaded Shaft – Project Packet here!

Angle Plate

The Angle Plate is your introduction to the milling machine. The milling machine – with which a rotating cutting tool is brought into contact with a stationary workpiece to produce shapes with typically flat surfaces – is one of the most common machine tools. You will build upon what you have already learned about print reading, precision measurement, metal cutting operations and tool geometries. You will be introduced to milling machine alignment, operation, tooling and safety. You will learn how to establish orientation relationships between features and interpret geometric dimensioning and tolerancing on prints.

Check out the Angle Plate – Project Packet here!

Steel Bushings

The Steel Bushings are your introduction to production techniques for the lathe. You will use carbide insert tooling, which ushered in a new era in metalworking in the mid-Twentieth Century with ultra fast cutting speeds, greatly improved ease of use, interchangeability and indexability. You will learn about precision boring on the lathe and some production techniques to manufacture parts efficiently, as well as aligning a workpiece in a four-jaw chuck. You will learn how to inspect surface finish and GD&T for cylindrical parts.

Check out the Steel Bushings – Project Packet here!

NIMS Mill 2.5 “Step Block”

The NIMS Step Block is a skill-developing exercise on the manual milling machine. You will use many of the skills and techniques you learned in previous projects, including: tramming a milling machine head, squaring up a block, locating and producing holes of different types, and finishing surfaces to achieve flatness, parallelism and perpendicularity. You will learn several new skills, including: using roughing end mills and solid carbide end mills, producing slots and steps, and producing precision holes using an offset boring head and other specialty tools. You will learn how to properly inspect GD&T tolerance of position controls with datum reference frameworks. You will also develop your understanding of the machinist’s thinking process by writing your own project planning worksheet.

Check out the NIMS Step Block – Project Packet here!

Plug Gage and Round Nuts

The Plug Gage and Round Nuts are skill-developing exercises on the manual lathe. You will use many of the skills and techniques you learned during manufacture of the Threaded Shaft in MACH 210 and the Steel Bushings in MACH 220, including: aligning a workpiece in a four-jaw chuck, using indexable carbide tooling, precision boring and single-point cutting screw threads. You will learn several new skills, including: using a collet chuck, generating features like radii, diamond knurls, internal screw threads and internal grooves, and inspecting these features with specialty measuring tools. You will learn how to properly determine the manufacturing tolerances for mating external and internal screw threads using standard thread tables and how to calculate pitch diameter using measurements taken with thread wires. You will also develop your understanding of the machinist’s thinking process by writing your own project planning worksheet.

Check out the Plug Gage and Round Nuts – Project Packet here!

Industrial Maintenance 101: Electric Motor Disassembly/Reassembly

This video is a walkthrough of a hands-on lab activity for a summer skilled trades exploration course. It is intended to demonstrate some of the day-to-day job tasks which would be performed by an Industrial Maintenance Mechanic. Electric motors are by far and away the most common machines in the world, and repairing them is a perfect example of industrial maintenance work. Students with no prior knowledge should be able to disassemble and reassemble an identical electric motor as shown in the video during a three hour session. Grab a motor and some hand tools and follow along!

Check out the Motor Lab Activity Sheet here!

Extracurricular Projects

Hand Scraper

Build your own hand scraper for finishing flat surfaces and reconditioning machine tools! If you’re a Laney College Machine Technology student, see your instructor for a free carbide scraper blade.

Check out the Hand Scraper – Print Packet here!

Machine Tool Alignment Gage

Build your own gage for inspecting the condition and alignment of machine tool way surfaces! If you’re a Laney College Machine Technology student, see your instructor for small components like springs and nuts.

Check out the Machine Tool Alignment Gage – Print Packet here!

Monochromatic Light Source

Build your own monochromatic light source for evaluating flat surfaces with interferometry! Electrical work should be done only by a licensed electrician.

Check out the Monochromatic Light Source – Print Packet here!

Graphite Air Bearing

Build your own aerostatic bearing which forces compressed air through porous graphite to ride on a cushion of air! Make a bunch of these and build a fun zero friction device! Get creative!

Check out the Air Bearing – Print Packet here!

Adjustable Height Vee Blocks

Build your own adjustable height vee blocks for precision runout inspection of shafts! If you’re a Laney College Machine Technology student, see your instructor for small components like screws, balls, springs and pins.

Check out the Adjustable Height Vee Block – Print Packet here!

For a breakdown of the design, a detailed step-by-step walkthrough of the build process and a demonstration of how to use the vee blocks, check out the series of Instagram posts linked below:

- Explanation of the design

- Making the vee inserts

- Making the base

- Making the vee carrier – part 1

- Making the vee carrier – part 2

- Making the front plate

- Making the clamping screws

- Making the adjustment screw

- Assembling the front plate and vee carrier; adhering and lapping the carbide pads

- Making and assembling the contacts; modifying the vertical guide pins

- Assembling the vee blocks

- Using the vee blocks

Small Diameter Shallow Bore Gage

Build your own SDSBG (pronounced “SDIZ-big”) for precision measurement of shallow bores (and bosses)! This design incorporates a Mitutoyo 513-402-10 indicator with a .65″ stylus length, but it can easily be modified to suit other makes and models. If you’re a Laney College Machine Technology student, see your instructor for small components like screws, springs and pins.

Check out the Small Bore Shallow Diameter Gage – Print Packet here!

For a breakdown of the design, a step-by-step walkthrough of the build process and a demonstration of how to use the SDSBG, check out the series of Instagram posts linked below: