This program is designed both for entry-level students and experienced craftspeople wanting to upgrade their skills. The up-to-date curriculum provides the current theoretical, technological and practical experience necessary for employment and advancement in the industry, and features the following elements:

- Theory and design of machine tools and machinery

- Properties of materials, including heat-treating

- Laboratory courses focused on hands-on operation of machine tools

- Technical mathematics

- Precision measurement

- Blueprint reading, geometric dimensioning and tolerancing (GD&T), and 3-D solid modeling

- CNC setup, operation and programming with CAD/CAM

The Laney College Machine Technology program’s commitment to currency in its curriculum ensures that students learn to use the industry’s latest technology, tools and equipment. This commitment is driven by constantly developing industry standards, the program’s industry-based faculty and technology partnerships with local industry.

With an experienced and dedicated faculty and a large shop filled with state-of-the-art equipment, the Machine Technology Program at Laney College is one of the best in the Bay Area — in fact, it’s one of the best in California!

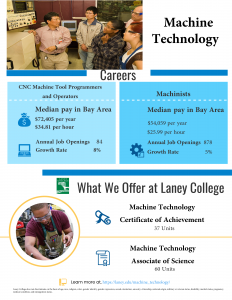

We have a 100% job placement rate for graduates and starting annual income in the Bay Area ranges from $55k – $87K plus benefits. Right now, we’re unable to meet employer demand for graduates – we need more students!

Fees and costs should not be a barrier to enrollment — the department awards between $20,000 and $50,000 in industry scholarships each year. And you don’t need any prior experience to enroll in the program!

2023-2024 Academic Year Update:

New Curriculum

The Machine Technology department is entering the final phase of a years-long modernization project. Since March of 2022, over $1 million in CNC machines and other related equipment has come into the machine shop. To go along with these acquisitions, we are offering new certificates and courses, and revamping existing courses. Our new certificate structure includes multiple stackable certificates to get students trained up and into the industry faster while also providing for continuing education. Our new courses cover advanced topics like geometric dimensioning and tolerancing (GD&T), 5-axis CNC machining, diamond turning and micromachining. And we are revisiting our introductory courses with exciting new projects and a new suite of instructional videos. One example of a new project is a telescope which students will manufacture during various courses and which will culminate in MACH 214 – Ultraprecision and Micromachining when they will diamond turn the mirrors! Another example is a part for a satellite deployer which students will machine in MACH 32 – Multi-Axis CNC Machining and which will fly to the International Space Station as part of NASA’s HUNCH program!

A Note about Mode of Instruction

Many courses will be offered face-to-face (“in-person”) only. For these courses, lectures and labs will take place on campus. Some other courses will be offered as “hybrid” courses with online lectures and face-to-face labs in the machine shop. Check the class schedule for details on which courses will be offered in which modality.

We began offering hybrid courses during the COVID-19 pandemic for health and safety reasons. But we have since found that some courses benefit from the hybrid format and it allows students to achieve greater success. In these courses, the online lectures and demonstrations are pre-recorded, so students can review them whenever their schedules permit. By the time they come in to the machine shop, they are well-prepared to start working on their projects and make the most of lab time. And they can even use the lecture and demonstration videos in the shop to help them with their projects. There are also many opportunities for one-on-one assistance during labs or during office hours held multiple times per week. And we have open hours in the computer lab and Chromebooks for lending to help students succeed in the online part of the course.

What is a Machinist?

A “machinist” is a maker — a precision metal cutter who uses specialized machines to produce precision parts for manufacturing in a wide range of industries, such as green energy, medical device manufacturing, and national defense.

The following skills and qualities are helpful for a career in machine technology:

- Mechanical aptitude

- Manual dexterity

- Interest in problem solving

- Ability to work independently

- Math proficiency

- Computer proficiency

- Effective Communication: listening, responding, presenting

- Commitment to continuing skill development throughout career

Job Classifications

- Machinist

- CNC Machinist

- CNC Machine Operator

- CNC Machine Setup Technician

- CNC Programmer

- Maintenance Machinist/Mechanic

- Mechanical Technician

- Parts Inspector

- Quality Control Technician

- Diamond Turning Technician

Questions?

Feel free to contact the department chair: Adam Balogh at abalogh@peralta.edu