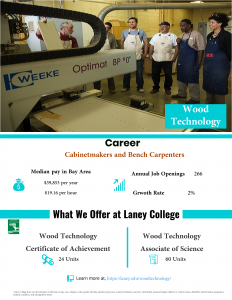

The Wood Technology curriculum offers instruction in woodworking for career-oriented students, and includes access to one of the best-equipped shops in Northern California. Employment-oriented students are assisted in finding work making custom furniture, kitchen cabinets, commercial fixtures, architectural millwork, and a wide variety of other wood products. Instruction is highly individualized and is designed to allow flexibility in learning speed, design experimentation, and areas of emphasis. The two primary goals of all classes are to make each student a safe machine and/or tool user, and to provide them with the problem-solving tools that relate to four-dimensional wood-based construction.

3 units, 3 hours lecture (GR)

Prerequisite: WDTEC 011.

Corequisite: WDTEC 10L, WDTEC 011.

Acceptable for Credit: CSU

Introduction to the technology of woodworking trades: Discussion and demonstration (SOP-safe operating procedures) of safe operation of stationary and portable power tools; milling, sawing, shaping, sanding, assembly, and finishing techniques; sharpening, machine maintenance, process planning. 0952.50

4 units, 12 hours lab, (GR)

Corequisite: WDTEC 010 and WDTEC 011.

Acceptable for Credit: CSU

Lab component of WDTEC 10: Laboratory practices to supplementing theory presented in WDTEC 10; practice of safe operation of stationary and portable power tools; milling, sawing, shaping, sanding, assembly, and finishing techniques; sharpening, machine maintenance, process planning. 0952.50

2 units, 1 hour lecture, 3 hours lab, (GR)

Corequisite: WDTEC 010, WDTEC 10L.

Acceptable for Credit: CSU

Drafting, layout, and detailing for the woodworking trades: Interpreting and producing shop drawings, applying joinery appropriate to various quality standard grades, solid wood forms, and geometric constructions. 0952.50

3 units, 3 hours lecture (GR)

Prerequisite: WDTEC 010, WDTEC 10L, WDTEC 011.

Corequisite: WDTEC 020L, WDTEC 021.

Acceptable for Credit: CSU

Continuation of WDTEC 010: 32mm cabinet-making systems; complex forms; machine maintenance; wood bending; advanced construction problems and techniques; finishing; hardware; adhesives and abrasives, hand tool conditioning and use; and related class projects. 0952.50

4 units, 12 hours lab, (GR)

Prerequisite: WDTEC 010, WDTEC 10L, WDTEC 011.

Corequisite: WDTEC 020, WDTEC 021.

Acceptable for Credit: CSU

Laboratory component of WDTEC 20: 32mm cabinet-making systems fabrication sequence, CNC operation, wood bending, advanced construction problems and techniques, finishing, hardware, adhesives and abrasives, hand tool conditioning and use, and related class projects. 0952.50

2 units, 1 hour lecture, 3 hours lab, (GR)

Prerequisite: WDTEC 010, WDTEC 10L, WDTEC 011.

Corequisite: WDTEC 020, WDTEC 020L.

Acceptable for Credit: CSU

Continuation of WDTEC 11: Interpreting and producing shop drawings, applying joinery appropriate to various quality standard grades, solid wood forms, and geometric constructions; using the computer as a tool for designing, drawing, generating cut lists, detailing cabinets plans, performing panel optimization plans, and cost/time analysis for the cabinetmaking industry. 0952.50

4 units, 2 hours lecture, 6 hours lab, (GR)

Prerequisite: WDTEC 020, WDTEC 020L, WDTEC 021.

Acceptable for Credit: CSU

Fundamentals of computer-assisted design (CAD), computer-assisted machining (CAM), fabrication techniques, and methodology: Theory, practice, and application with CAD/CAM software and CNC machinery commonly used in the contemporary woodworking industry. 0952.50

4 units, 2 hours lecture, 6 hours lab, (GR)

Advanced principles of computer-assisted design (CAD), computer-assisted machining (CAM), fabrication techniques, and methodology: Theory, practice, and application with CAD/CAM software and CNC machinery commonly used in the contemporary woodworking industry. 0952.50

1 – 2 units, 3 – 6 hours lab, (GR)

Prerequisite: Student must have completed at least 1 semester of WDTEC courses.

Open laboratory: Upgrading of specific wood technology skills and selected wood technology projects. 0952.50

2 units, 1 hour lecture, 3 hours lab, (GR or P/NP)

Instruction and practice in the selection, sharpening, conditioning, and use of high-quality traditional woodworking hand tools: Emphasis on hand tools from Japan—sharpening stones, chisels, planes and saws, and traditional Japanese joinery. 0952.50

2 units, 1 hour lecture, 3 hours lab, (GR or P/NP)

Prerequisite: WDTEC 210A.

Skills, tools and information acquired in WDTEC 210A are put to use in the construction of a series of projects based on traditional Japanese joinery construction: Specialty tools, chamfer, rabbet, and plow planes, kebiki, azebiki saws, yariganna (spear planes) and more refined techniques of sharpening, planing and joinery construction. 0952.50

2 units, 1 hour lecture, 3 hours lab, (GR or P/NP)

Prerequisite: WDTEC 210B.

Continuation of WDTEC 210B: Development and presentation of advanced projects, with exploration of more substantial and mature joinery work 0952.50

2 units, 1 hour lecture, 3 hours lab, (GR or P/NP)

Prerequisite: WDTEC 210C.

Fundamentals of design and construction of small structures for the yard and garden: Focus on developing designs with structural joinery construction projects. 0952.50

2 units, 2 hours lecture (GR)

CAL-OSHA 30-hour general industry training: Industry Standards for regulations covered by the Occupational Safety and Health Administration (OSHA) Standards for the General Industry 29 CFR 1926. 0952.50

.5 units, 1.5 hours lab, (P/NP)

Introduction to the skilled trades Wood Technology: topics include safety, career opportunities, and hands on experience. Part of a four part series trades survey class including Welding 255, Carpentry 255, Machine Technology 255. 0952.50

4 units, 2 hours lecture, 6 hours lab, (GR or P/NP)

Training in basic woodworking and communication skills: Lecture, demonstration, and hands-on practice with tools and materials of cabinet and furniture making, safe and efficient application of machine-oriented woodworking techniques; emphasis on communication and problem-solving skills related to woodworking industry. 0952.50

1 – 4 units, 3.43 – 17.15 hours lab, (GR)

Supervised employment providing opportunities in wood technology or a related field: Develop desirable work habits, become a productive, responsible individual, and extend education experience with on the job training. Students may reenroll for a maximum of 16 units for occupational or a combination of general and occupational work experience education (including Regular and Alternate Plan and General/Occupational/Apprentice Work Experience). 0952.50

1 – 4 units, 3 – 12 hours lab, (GR)

Supervised employment providing opportunities in wood technology or a related field: Develop desirable work habits, become a productive, responsible individual, and extend education experience with on the job training. A maximum of 14 units may be earned during one enrollment period. 0952.50