The Laney College Machine Technology program stays at the forefront of industry advancements by continually updating its curriculum to reflect the latest technology, tools, and equipment. This commitment is driven by evolving industry standards, experienced faculty with real-world expertise, and strong partnerships with local businesses.

Department Overview

This program is designed both for entry-level students and experienced craftspeople wanting to upgrade their skills. The up-to-date curriculum provides the current theoretical, technological and practical experience necessary for employment and advancement in the industry, and features the following elements:

- Theory and design of machine tools and machinery

- Properties of materials, including heat-treating

- Laboratory courses focused on hands-on operation of machine tools

- Technical mathematics

- Precision measurement

- Blueprint reading, geometric dimensioning and tolerancing (GD&T), and 3-D solid modeling

- CNC setup, operation and programming with CAD/CAM

What Is A Machinist?

What Is A Machinist?

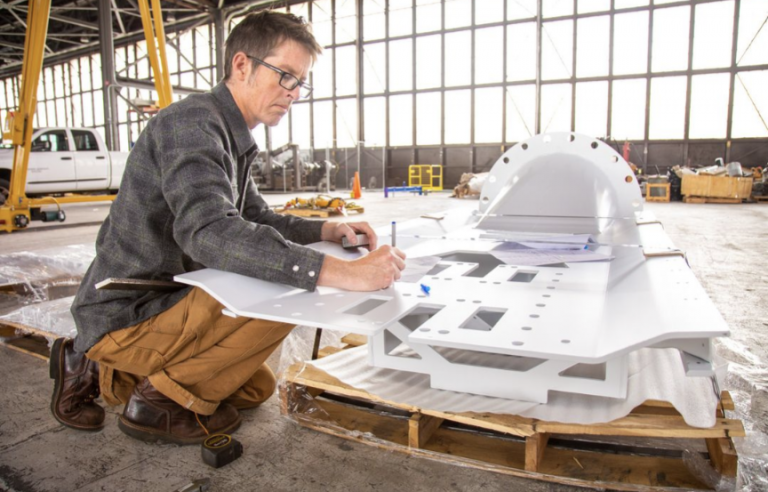

A “machinist” is a maker — a precision metal cutter who uses specialized machines to produce precision parts for manufacturing in a wide range of industries, such as green energy, medical device manufacturing, and national defense.

The following skills and qualities are helpful for a career in machine technology:

- Mechanical aptitude

- Manual dexterity

- Interest in problem solving

- Ability to work independently

- Math proficiency

- Computer proficiency

- Effective Communication: listening, responding, presenting

- Commitment to continuing skill development throughout career

New Curriculum & Mode Of Instruction

New Curriculum & Mode Of Instruction

New Curriculum:

The Machine Technology department is nearing completion of a years-long modernization project. Since March of 2022, over $1 million in CNC machines and other related equipment has come into the machine shop. To go along with these acquisitions, we are offering new certificates and courses, and revamping existing courses. Our new certificate structure includes multiple stackable certificates to get students trained up and into the industry faster while also providing for continuing education. Our new courses cover advanced topics like geometric dimensioning and tolerancing (GD&T), 5-axis CNC machining, diamond turning and micromachining. And we are revisiting our introductory courses with exciting new projects and a new suite of instructional videos. One example of a new project is a telescope which students will manufacture during various courses and which will culminate in MACH 214 – Ultraprecision and Micromachining when they will diamond turn the mirrors! Another example is a part for a satellite deployer which students will machine in MACH 32 – Multi-Axis CNC Machining and which will fly to the International Space Station as part of NASA’s HUNCH program!

Mode Of Instruction:

Most courses will be offered face-to-face (“in-person”) only. For these courses, lectures and labs will take place on campus. Some other courses will be offered as “hybrid” courses with online lectures and face-to-face labs in the machine shop. Check the class schedule for details on which courses will be offered in which modality.

We began offering hybrid courses during the COVID-19 pandemic for health and safety reasons. But we have since found that some courses benefit from the hybrid format and it allows students to achieve greater success. In these courses, the online lectures and demonstrations are pre-recorded, so students can review them whenever their schedules permit. By the time they come in to the machine shop, they are well-prepared to start working on their projects and make the most of lab time. And they can even use the lecture and demonstration videos in the shop to help them with their projects. There are also many opportunities for one-on-one assistance during labs or during office hours held multiple times per week. And we have open hours in the computer lab and Chromebooks for lending to help students succeed in the online part of the course.

Career Opportunities

Career Opportunities

With an experienced and dedicated faculty and a large shop filled with state-of-the-art equipment, the Machine Technology Program at Laney College is one of the best in the Bay Area — in fact, it’s one of the best in California!

We have a 100% job placement rate for graduates and starting annual income in the Bay Area ranges from $55k – $87K plus benefits. Right now, we’re unable to meet employer demand for graduates – we need more students!

Fees and costs should not be a barrier to enrollment — the department awards between $20,000 and $50,000 in industry scholarships each year. And you don’t need any prior experience to enroll in the program!

A degree in Machine Technology opens the door to a wide range of exciting and rewarding career opportunities. As a skilled machinist or technician, you’ll be at the forefront of manufacturing, working with advanced machinery to create precision parts and tools that are essential in industries such as aerospace, automotive, healthcare, and electronics.

Here are some of the career paths you can pursue with a Machine Technology degree:

-

CNC Machinist: Operate and program computer numerical control (CNC) machines to produce high-precision components used in various industries.

-

Tool and Die Maker: Design and build specialized tools, dies, and molds used in manufacturing processes, ensuring that parts are produced with exact specifications.

-

Manufacturing Technician: Work in production settings, maintaining and troubleshooting machinery, and ensuring that manufacturing processes run smoothly and efficiently.

-

Quality Control Inspector: Ensure that products meet industry standards and specifications by conducting detailed inspections and tests on finished parts and tools.

-

Maintenance Machinist: Specialize in repairing and maintaining industrial machinery, ensuring that equipment operates at peak performance.

-

Production Supervisor: Oversee manufacturing teams, manage workflows, and ensure that production goals are met while maintaining high-quality standards.

Why Choose a Career in Machine Technology?

-

High Demand: Skilled machinists and technicians are in high demand across various industries, making it easier to secure employment after graduation.

-

Competitive Salaries: Starting salaries in the Bay Area range from $55K to $87K annually, with potential for growth as you gain experience.

-

Advancement Opportunities: With experience and additional training, you can advance into higher-paying roles such as production management, engineering, or specialized machining.

-

Job Security: Manufacturing is a backbone of the economy, and machinists play a critical role in keeping industries running. This ensures long-term job security and stability.

Whether you're looking to start a new career or enhance your skills, a Machine Technology degree from Laney College provides the training and credentials you need to succeed in this dynamic field.

Contact Us

Department Co-Chairs

Adam Balogh

abalogh@peralta.edu

Dean

Alejandria Tomas

atomas@peralta.edu

Learning & Career Pathways

Building & Skilled Trades

Career & Technical Education & KASH

Location

Building G, Room 100

(G-100, Lower Level)

Follow Laney Machine Tech

Machine Tech Virtual Tour

Degrees & Certificates

This Certificate provides students with theoretical knowledge and hands-on skills required for entry-level work in precision manufacturing. Coursework includes shop safety,

This Certificate prepares students for work as a manual machinist. The certificate builds upon knowledge gained and skills developed in the Basic Manufacturing certificate. Students achieve competency in the operation of manual machine tools, such as mills, lathes and surface grinders.

This Certificate prepares students for work as a CNC machinist, CNC machine operator, CNC setup technician or CNC programmer.

This Degree is a career technical education program that prepares students for work as a machinist, manual machinist, CNC machinist, CNC operator, CNC setup technician or CNC programmer.

This Certificate is a career education program which prepares students for the highest level of work in precision manufacturing.

This multi-disciplinary career technical education Certificate prepares students for work in a wide range of industries.

Looking for some guidance?

Below is our recommendation for which courses to take during each semester to complete the Machine Technology AS degree within two years.

| Course # | Course Title | Units |

| MACH 20 | CAD Solid Modeling with SolidWorks | 4 |

| MACH 205 | Engineering Drawings | 3 |

| MACH 210 | Introduction to Machining | 5 |

| MATH 220A* | Technical Mathematics with Algebra – Part 1 (Lab) | 0.5 |

| MATH 220B* | Technical Mathematics with Algebra – Part 2 (Lab) | 0.5 |

| Course # | Course Title | Units |

| MACH 30 | Introduction to CNC Setup, Operation and Programming | 4 |

| MACH 220 | Intermediate Manual Machining | 5 |

| MATH 220C* | Technical Mathematics with Algebra – Part 3 (Lab) | 0.5 |

| MATH 220D* | Technical Mathematics with Algebra – Part 4 (Lab) | 0.5 |

| Course # | Course Title | Units |

| MACH 31 | Advanced CNC with CAD/CAM Programming | 4 |

| MACH 230 | Machine Technology III | 5 |

| MATH 220E* | Technical Mathematics with Geometry – Part 1 (Lab) | 0.5 |

| MATH 220F* | Technical Mathematics with Geometry – Part 2 (Lab) | 0.5 |

| Course # | Course Title | Units |

| MACH 32 | Multi-Axis CNC Machining | 4 |

| WELD 205 | Introduction to Welding | 3 |

| MATH 220G* | Technical Mathematics with Trigonometry (Lab) | 1 |

CNC Machines

- Haas UMC500 5-axis machining center

- (2) Haas VF2 machining center

- Haas Super Mini Mill

- Haas Mini Mill

- Haas ST-10Y turning center with Y-axis and live tooling

- Haas ST-10 turning center with live tooling

- Haas SL-10 turning center

CNC Machine Accessories

- Haas HTS-400 tool presetter

- Haas HSF-325 shrink fit machine

- Haas HRT160 4th axis rotary table

- (2) Haas TRT-100 5-axis tilting rotary table

- (5) Haas control simulators

Manual Machines

- (10) Vertical knee-style milling machine (Bridgeport, Sharp)

- (13) Engine lathe (LeBlond, Monarch, Sharp, Acra)

- (2) Surface grinder (Chevalier)

- Cylindrical grinder (Myford)

- Tool and cutter grinder (Cincinnati)

- Drill press (Arboga)

- Horizontal bandsaw (Baileigh Industrial)

- Vertical bandsaw (Powermatic)

Auxiliary Equipment

- Pedestal grinders

- Buffer/polisher

- Belt sander

- Carbide tool grinder

- Semi-automatic drill sharpener (Darex)

- Single lip cutter grinder (Deckel)

- Heat treating furnace (Sentry)

- Bead blasting cabinet

- Portable coolant recycling unit (Freddy)

Inspection Equipment

- Zeiss Duramax automatic coordinate measuring machine (CMM)

- Mitutoyo Crysta manual coordinate measuring machine (CMM)

- Mitutoyo PH-series profile projector/optical comparator

- Olympus STM7 measuring microscope

- Filmetrics Profilm3D white light interferometer

- Davidson Optronics D-309L planointerferometer

- Zygo Verifire QPZ 1K interferometer

- Rockwell hardness tester

Digital Fabrication Shop

Free to use and available to all Laney students, the FabLab requires no prior experience. Digital fabrication is a workflow for creating physical objects through digital design technologies and automated tools.

.png?width=500&height=330&name=Laney%20College%20Enrollment%20(3).png)

Unlock Financial Aid for College Expenses

Transfer To A University

Transfer To A University

Laney College's AA-T and AS-T degrees guarantee junior standing admission to the CSU system, with priority for local CSU campuses in similar programs. Consult a counselor or transfer specialist for details.

.png?width=60&height=60&name=CTE%20(6).png) Meet With A Counselor

Meet With A Counselor

Counselors can help you create a Student Educational Plan (SEP) to outline the courses needed for an Associate’s degree, transfer, or certificate, even if you're unsure of your educational goals.

.png?width=60&height=60&name=CTE%20(10).png) Uncertain About Your Career Path?

Uncertain About Your Career Path?

We provide support with career exploration, self-assessment as well as the major and career decision making process to help all Laney students achieve career satisfaction and success.